Characteristics

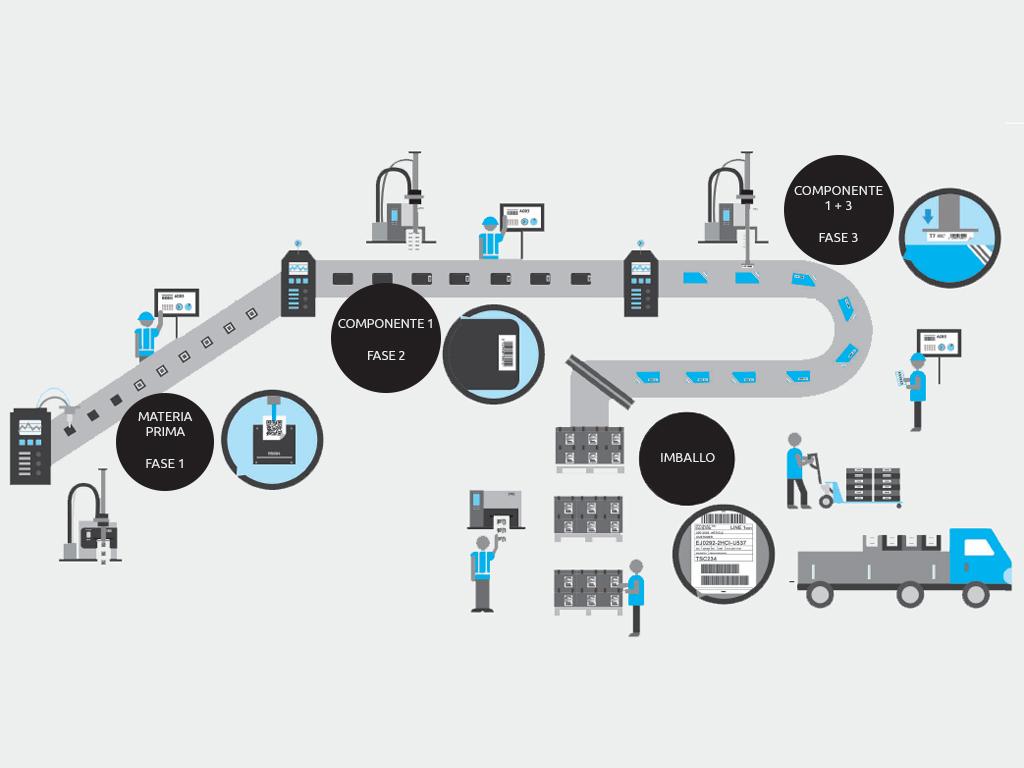

- Electronic traceability of all the lots worked (coils, billets, strips, bundles, workpieces, batches, etc.) by Machine / Production Order / Date / Shift / Operator / Result / Rework.

- Product identification and tracking status at all processing stages with barcode/RFID.

- Container identification and product tracking, by automatically associating the contents to the container for the phases in which it is impossible to identify each part / lot.

- View of the stock status of each order at different processing stages, with possible search by applying various filters (Status, Machine, Production Order, Article, Operator, Dates, Batch, etc.).

- Full integration with the management system, by eliminating laborious operations in entering tracking data manually by batch/lot; testing measurements.

- Verification of each lot being loaded in the machine to check in real time the compatibility with the status, production phase and production specifications to prevent errors.

- Simple and immediate interface with field operators.

- Traceability of controls, measurements and tests performed by the operator on each lot, thus eliminating the need to manually fill complex hard copy forms.

Benefits

- Availability of integrated real-time, complete and shared information for both production progress control and product tracking.

- Elimination of paperwork, which is very costly to complete in the field and later manage for office search and/or logging.

- Zeroing of transcription and system entry errors.

- Immediate visibility of processes for each lot throughout the production cycle.

- Immediate stock visibility by each lot phase/status.

- Centralized storage of the trend in production, process and inventory to allow tracking of the status of machines and process for optimisation.

Case History

Ori Martin

For Ori Martin, Stain has developed a specific suite for product tracking on production equipment, with real-time tracking data, detection of software real costs and clean and reliable data.