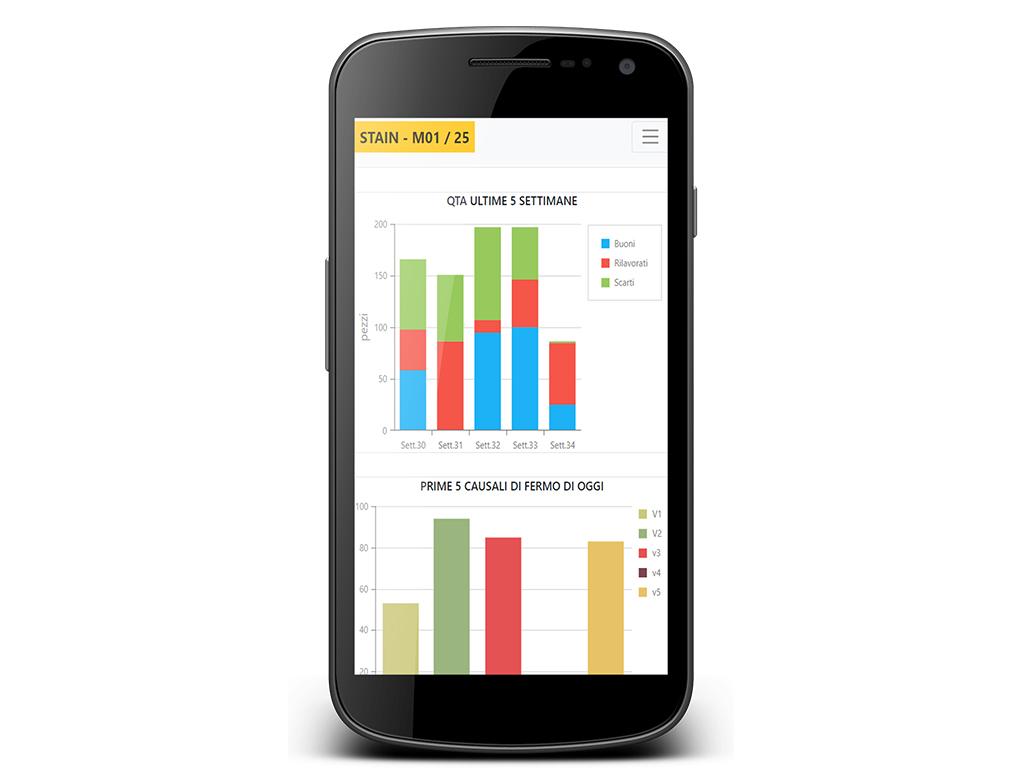

Operators/departmental managers can interact with STAIN+ from mobile devices, such as tablets or smartphones, without going to a fixed PC terminal to:

- view machine status with current production details.

- view production orders in the sequence received by the ERP system and select the order to be activated in the machine with the relevant details.

- log reasons for machine stoppages by selecting from a list or barcode scanning, using the camera on the mobile device, or scanner if integrated in the device.

- log waste associated with production in progress or production already completed, detailing the actual quantity of waste and reasons for it when known.

- log the presence of direct and indirect operators working in plants.

Operators may carry out manual production tasks (e.g. manual assembly of parts) or other tasks that need to be tracked to calculate the time used by each person (e.g. a toolmaker may carry out tasks on machinery, preparations in the tool shop, provide support etc.).

Manual part manufacturing tasks are manual production activities carried out by one or more operators at a workstation (e.g. assembly). With mobile STAIN+, operators can:

- open a production order using the relevant reference codes.

- register parts produced. STAIN+ automatically counts production time used and performance speed.

- log downtimes with reasons and waste.

Operators may carry out manual production tasks (e.g. manual assembly of parts on a bench) or control the progress of production machinery not automatically connected to STAIN+. In both cases operators, with a few simple entries, can control production progress and monitoring as if data were automatically collected by STAIN+. In this case, having a mobile device is very convenient for operators because workstations are not fixed, but are set up on a case-by-case basis, depending on the requirements of the job, and the tool for logging and monitoring production accompanies the operator and not the workstation. Even with machines where connecting piece-counters to have automatic data is not required, mobile power helps operators who use the tool accompanying them when in position on machines where production start and finish records are necessary. Using the mobile technology it is possible to:

- open a production order using the relevant reference codes.

- register parts produced. STAIN+ automatically counts production time used and performance speed.

- log downtimes with reasons.

- log waste with reasons.

These tasks are not necessarily linked to a production order or registration of parts, but they track all possible tasks that operators may carry out during a shift, calculating the time allocated using the sum of times for the various tasks.

- With mobile Stain+ MES tasks can be configured freely by managers.

- For each task, it is possible to configure the parameters requested of operators on the basis of the task being logged, enabling very advanced customisation of the interaction between operators and the system.

- Operators can record the start or end of the current task.

- Depending on the configuration set up by managers, operators are only asked for the information configured for each type of entry to be logged.

- During each entry, operators can see the time status for their allocated tasks to facilitate calculations with respect to the time allocated.

- Mobile STAIN+ MES stores and calculates times and tasks for real time monitoring of indirect tasks and statistical analysis.